- Home

- Custom Plastic Enclosures and Boxes

Feiling offers one-stop customization service for plastic enclosures and boxes, covering everything from design to batch delivery. We do all the work, including drawing design, mold design and manufacture, injection molding, surface treatment, painting and assembly, ensuring our mold and tool design capabilities and a fully managed factory result in a reliable product quality and short delivery period.

We customize an extensive array of plastic enclosures and boxes for our customers, including electronic equipment enclosure boxes, industrial enclosures, din enclosures, handheld enclosures, IP68 enclosures (waterproof up to 1m underwater), and PCB mounting enclosures. Each is made from a variety of plastic materials and equipped with different metal fittings. Our warehouses for raw materials and parts are clearly marked and strictly managed to ensure an organized manufacturing process. We also use materials provided by clients upon request. The enclosure weight ranges between 10 to 2500g, and are processed through a variety of surface treatments, including extreme polishing or a matte surface treatment, then printed with logos and patterns according to your needs. Our one-stop shop for customization services saves customers time and money.

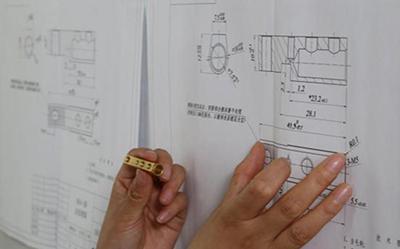

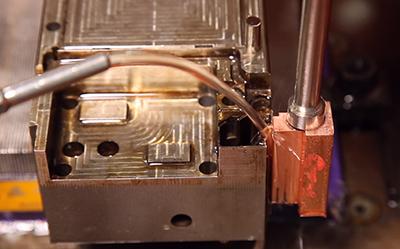

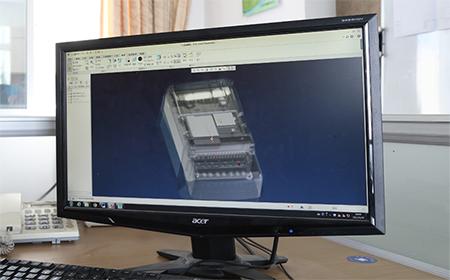

Backed by extensive experience in the production of plastic enclosures, Feiling owns and operates an independent mold manufacturing and machining center with a highly skilled mold design and R&D team to provide custom services for plastic enclosures according to customer requirements. We carry out design, manufacturing, and machining of complete mold sets using advanced CAM technology, allowing us to design molds according to customer provided samples or drawings, as well as produce one-to-one rapid mold or one-to-eight large mold. We have an independent mold manufacturing workshop equipped with advanced mold making and processing equipment, ranging from high-precision machining centers, multi-model high/medium/low speed wire cutting machines, EDM machines, EDM hole drilling machines, and water mills to ordinary milling and drilling equipment, allowing us to produce molds accurately and efficiently. Mold size is less than 1m.

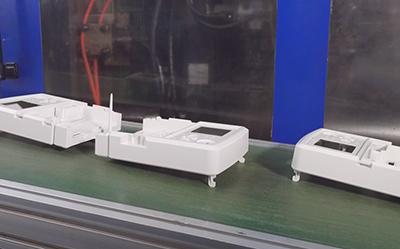

Equipped with 3 injection molding workshops, including a dust-free injection molding workshop with a total of 78 injection molding machines, we carry out the production of a variety of plastic enclosure components with the injection weight ranging from 10g to 1000g.

The injection molding workshop is equipped with 18 automatic hot melt machines, a centralized feeding system and a drying and preheating system to ensure the injection molded product quality. Our self-developed production lines for hot melting and automatic assembly significantly improve production efficiency. In addition, the newly built dust-free workshop enhances the quality of the injection molded transparent products, ensuring surfaces are clear and clean. We produce satisfactory samples from mold opening to trial production within 35 days.

Feiling offers plastic injection finishing services and performs a series of surface treatments such as grinding, polishing and cleaning on the injection plastic enclosures. Different surface treatments such as sandblasting and powder coating are carried out to achieve specific appearance qualities according to your needs.

We are also equipped with laser marking machines that can print various patterns, trademarks, texts, barcodes, or QR codes onto your enclosure products.

Feiling also provides plastic injection parts assembly services for assembling plastic injection parts and related metal fittings and connection wires in advance to save time. Using specially developed equipment, we complete installation of roughly 400,000 screws per day.

There are five 15m standard assembly lines in the assembly shop, achieving a daily production of 50,000 enclosure sets.

We are committed to the production of satisfactory products through the continuous improvement of our manufacturing processes.

-

Wide Material SelectionWe utilize a variety of plastic materials, including PC (polycarbonate), ABS, PBT and more. Each is stored in a strictly managed warehouse covering more than 3350m2 . These durable materials are prepared for the support of your custom project.

Wide Material SelectionWe utilize a variety of plastic materials, including PC (polycarbonate), ABS, PBT and more. Each is stored in a strictly managed warehouse covering more than 3350m2 . These durable materials are prepared for the support of your custom project. -

Plastic Enclosure DesignWith extensive experience, Feiling will design practical and reliable plastic enclosures to meet customer requirements. We are glad to support a variety of plastic projects and design customer industrial products. Our services include design, drawing, modeling, and subsequent manufacturing.

Plastic Enclosure DesignWith extensive experience, Feiling will design practical and reliable plastic enclosures to meet customer requirements. We are glad to support a variety of plastic projects and design customer industrial products. Our services include design, drawing, modeling, and subsequent manufacturing. -

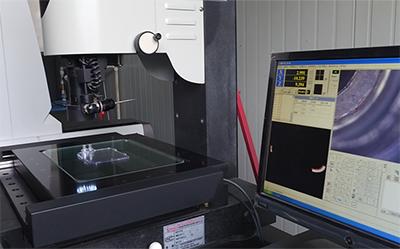

Quality ControlIn order to ensure product quality, we are fully equipped with extensive, professional testing equipment. Our professional QC specialists are responsible for incoming quality control (IQC), in-process quality control (IPQC) and outgoing quality control (OQC) in strict accordance with ISO9001 quality system standards.

Quality ControlIn order to ensure product quality, we are fully equipped with extensive, professional testing equipment. Our professional QC specialists are responsible for incoming quality control (IQC), in-process quality control (IPQC) and outgoing quality control (OQC) in strict accordance with ISO9001 quality system standards.

Ready to get started?

Or have any question about any of our plastic enclosures and boxes manufacturing service?

- Custom Plastic Enclosures and Boxes

- Plastic Injection Molds Designing and Production

- Plastic Injection Molding

- Finishing and Painting

- Plastic Enclosure Assembling

- Plastic Enclosures and Boxes

- Add.: No.429-477 Weiyi Road, Andong Town, Cixi City, Zhejiang Province

- Tel.: +86-574-63479806

- Email: ET@chinafeiling.com